The Key to Mining Profitability: Mineral Processing Tests Are Essential

Mineral processing test studies are the primary basis for evaluating whether a mineral resource has industrial value. Due to the differences in mineral composition of ores from different regions, mineral processing techniques and parameters also vary significantly. This is why the construction of a mineral processing plant cannot simply copy the process flows of other plants. The results of mineral processing tests have a direct impact on the reasonable determination of process flow, equipment selection, product schemes, and technical-economic indicators for mineral processing design. Moreover, they serve as the foundation for whether a mineral processing plant can successfully reach design targets and achieve economic benefits after production starts.

Through mineral processing test studies, it is possible to identify the best processing parameters and flows for specific ores, minimize processing costs, and maximize the utilization of mineral resources. This, in turn, allows mining enterprises to achieve the greatest economic and environmental benefits.

Why Are Mineral Processing Tests So Important?

Mineral processing tests are not a foreign concept to any mining operation. But why are they so essential? What impact will the lack of testing have on the efficiency of a mining operation?

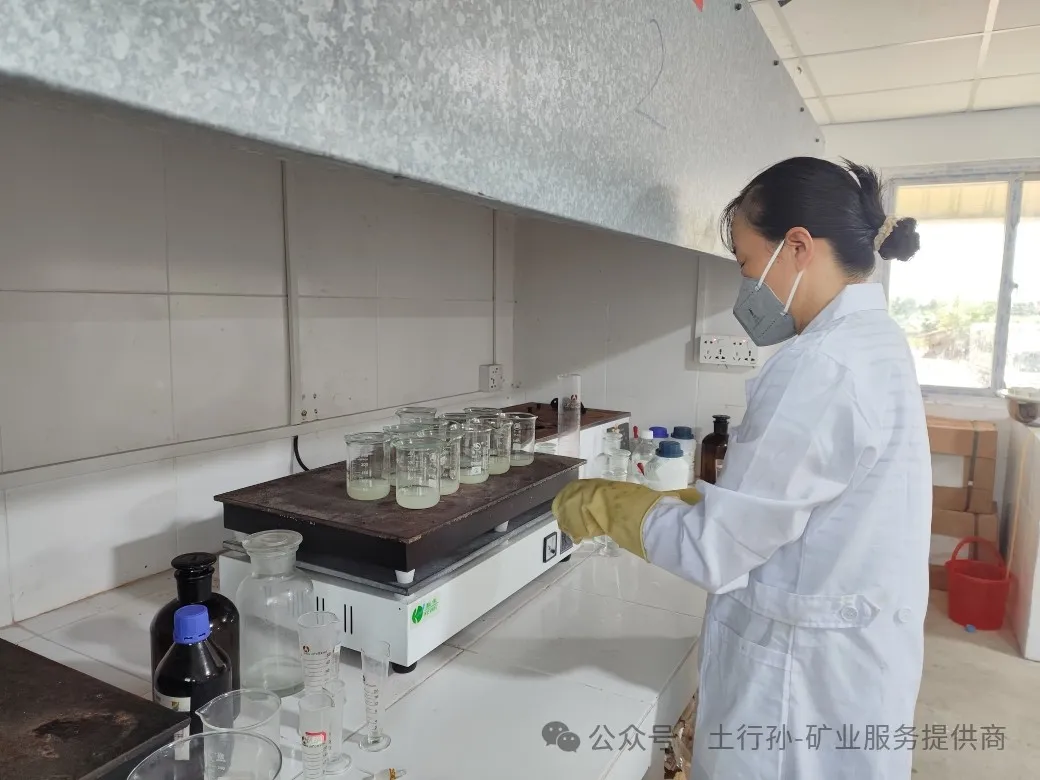

In the rapidly evolving mining industry, the importance of mineral processing tests cannot be overstated. These tests are crucial for determining the most efficient and sustainable methods to extract valuable minerals from ore. At Shaanxi TuXingSun Mining, we have been offering mineral processing tests for our clients, using these tests to maximize economic and environmental benefits for them.

Economic Benefits

The significance of mineral processing tests in terms of economic benefits cannot be ignored. By determining the nature of the ore and selecting appropriate mineral processing technologies and equipment, unnecessary economic losses during the construction and commissioning of a mineral processing plant can be avoided. This also ensures that the final processing indicators of the plant are met.

Foundation for Assessing Mine Value

Mineral processing tests form the foundation for evaluating the value of a mine and determine the economic profitability of a processing plant. Under current technological and economic conditions, mineral processing tests decide whether an ore can be mined and utilized. For ores with low grades, fine distribution, or high harmful impurity content, these tests provide assurance of recovery rates and offer investors confidence in the technical and economic viability of plant operations.

Data for Mineral Processing Plant Design

The industrial indicators obtained from mineral processing tests provide necessary raw data for the design of mineral processing plants. These data include ore characteristics, processing schemes, processing indicators, equipment parameters, and consumption rates of water, electricity, and materials. If the test results are both economically and technically feasible, the design of the processing plant can proceed. If any aspect is infeasible, the design process cannot continue. Therefore, mineral processing tests are the foundation for the future construction of processing plants.

Comprehensive Utilization of Mining Resources

Mineral processing tests play a crucial role in the comprehensive utilization of mining resources. Most minerals in nature are associated with other minerals, making the composition of ore complex and varied. Through processing tests, these primary minerals and associated minerals can be effectively separated, maximizing resource utilization. Not only can the recovery rate of the primary mineral be improved, but the associated minerals can also be fully utilized, preventing resource waste.

Environmental Benefits

In terms of environmental benefits, the importance of mineral processing tests lies in resource conservation and environmental friendliness. This includes the recycling of waste slag, wastewater, and other byproducts produced during processing. These waste products often contain valuable components that can be separated and recovered through mineral processing methods, reducing resource waste and lowering mining costs. Additionally, tests ensure that toxic chemicals are minimized or replaced, reducing environmental pollution.

Traditional mineral processing methods often involve chemicals harmful to the environment, leading to toxic waste in water and tailings that pose serious ecological threats. However, by improving processing methods and using environmentally friendly chemicals, the production of harmful substances can be greatly reduced, thereby protecting the environment.

TuXingSun Mining: Your Partner for Mineral Processing Tests

Shaanxi TuXingSun Mining is dedicated to the development and utilization of mineral resources. We understand the importance of mineral processing tests in mine construction. No mining operation has ever gone bankrupt due to conducting mineral processing tests, but many have failed to meet processing targets and plant efficiency due to the lack of systematic testing. Thus, mineral processing tests are an indispensable part of mine construction. Shaanxi TuXingSun Mining will continue to uphold this philosophy, continuously improve our technical and testing capabilities, and provide our clients with the highest quality services and solutions. We believe that through continuous technological innovation and scientific testing methods, Shaanxi TuXingSun Mining will achieve even greater success in the mining industry.

- Random article

- Popular articles

- Popular comments

- Tin ore gravity separation+roasting+magnetic separation+gravity beneficiation process

- How to Extract Gold Using Mercury

- Gravity combined beneficiation process for black and white tungsten ore

- Laterite Nickel Ore: Pyrometallurgical Treatment

- Lithium ore heavy medium beneficiation process

- Zirconium Ore Separation: Gravity and Magnetic Methods

- Chromite Processing: Gravity, Magnetic, and Flotation Separation

Leave a message with your needs or comments

Add comment: