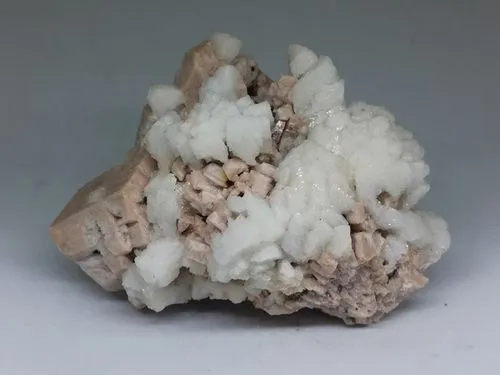

The mineralization of Baigangyan type feldspar minerals is uniform and of stable quality, with potassium feldspar and sodium feldspar accounting for about 50-60%. The main gangue minerals include quartz, mica, and iron containing minerals. Usually, this type of deposit requires flotation treatment to obtain feldspar concentrate.

The beneficiation process flow of Baigangyan type feldspar

1.Crushing operation:

Coarse crushing:The raw ore is first subjected to coarse crushing by a jaw crusher, crushing it into smaller particles.

Medium crushing:Then, the coarse ore is further crushed to a size of about 20mm through a cone crusher.

2.Grinding and grading operations:

Wet grinding:The crushed ore enters the rod mill for wet grinding, and the grinding products are screened through a drum screen to ensure that the ore particle size reaches a certain fineness.

Desliming:The grinding product undergoes desliming operation through a cyclone and spiral classifier to remove fine clay impurities of -200 mesh level.

3. Flotation operation :

Mica flotation: In weakly acidic media, cationic collectors (mainly amine collectors) are used to flotation mica, purify mica, and wet screen it through an 80 mesh vibrating screen. Wet mica larger than 80 mesh can be sold to mica processing plants.

Iron removal flotation:In weakly acidic media, anionic collectors (mainly sulfonated oil) are used to remove iron containing minerals.

Separation of feldspar and quartz:In weakly acidic media, a combination collector is used for the separation flotation of feldspar and quartz.

Technological advantages

1.Efficient Separation:Through flotation operations, impurities such as mica, iron minerals, and quartz can be effectively separated, thereby obtaining high-purity feldspar concentrate.

2.Flexible Adaptation:Based on mineral composition and quality requirements, the sequence of flotation operations and the use of reagents can be adjusted appropriately to meet different production needs.

3.Improve product quality:Through precise flotation technology, the quality of feldspar products can be improved to meet the strict requirements of users such as glass factories.

4.Energy saving and environmental protection:Compared with traditional crushing and grinding processes, flotation processes have advantages such as low energy consumption and environmental friendliness.

The beneficiation process of Baigangyan type feldspar has advantages such as efficient separation, flexible adaptation, improved product quality, and energy conservation and environmental protection, providing strong support for the development and utilization of Baigangyan type feldspar deposits.

For more professional suggestions? Contact us!

Warm Tips:If you want to know more information, like quotation, products, solutions, etc.,

Contact: Pingheng

Tuxing Sun Mineral Processing Expert

Wechat/whatapp:+86 18092529083

Email:[email protected]

- Random article

- Popular articles

- Popular comments

- Hg-ore gravity separation process

- Sand gold beneficiation process

- Combined process of laterite nickel ore selection and smelting(oxidized ore)

- Lithium ore combined beneficiation process

- Chromite Gravity and Magnetic Separation Process

- Chromite Gravity, Magnetic, and Electric Separation Process

- Antimony Ore Hand Picking Process for Color Sorting

Leave a message with your needs or comments

Add comment: