The phosphorus ore scrubbing and desliming+flotation process is a process flow for treating heavily weathered and clay rich phosphate rock ore. The main purpose of this process is to improve the quality and purity of phosphate ore through scrubbing, desliming, and flotation treatment, thereby achieving better economic benefits.

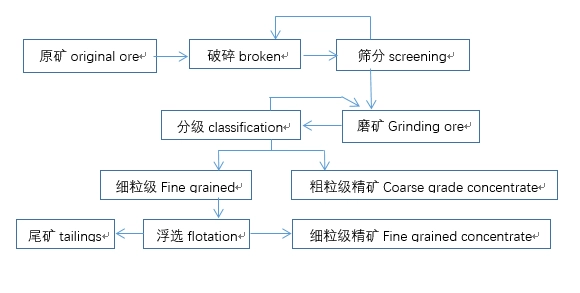

Phosphate ore scrubbing and desliming+flotation process flow

1.Ore crushing: :Crushing phosphate rock ore to achieve appropriate particle size for subsequent processing.

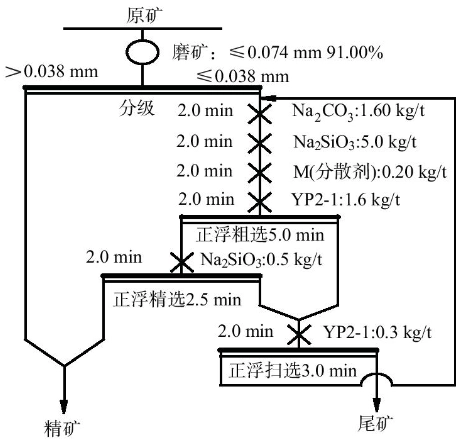

2.Scrubbing and desliming:Scrubbing and desliming the crushed ore to remove impurities such as clay and sediment from the surface of the ore. Scrubbing and desliming usually use specialized desliming equipment, such as scrubbing machines, desliming machines, etc., for treatment.

3.Flotation:The slurry after scrubbing and desliming is subjected to flotation treatment to separate useful minerals such as apatite and collophane. During the flotation process, it is necessary to add appropriate flotation reagents to improve the flotation efficiency of useful minerals.

4.Concentrate processing:Further processing of the flotation concentrate, such as concentration and filtration, to improve its purity and quality.

Technological advantages

1.Pre discarding tailings or obtaining concentrate:By scrubbing, desliming, and flotation treatment, most of the tailings and impurity minerals can be removed at an earlier stage, thereby obtaining a purer concentrate, saving subsequent processing costs and time.

2.Saving reagents: Due to the effective removal of impurities and minerals through scrubbing, desliming, and flotation treatment, the use of flotation reagents can be reduced, thereby reducing production costs.

3.Improving flotation indicators: By scrubbing, desliming, and flotation treatment, the content and purity of phosphorus in phosphate ore can be increased, thereby improving flotation indicators and increasing economic benefits.

The phosphorus ore scrubbing and desliming+flotation process is an effective method for phosphorus ore processing, which can improve the quality and purity of phosphorus ore, thereby achieving better economic benefits

Typical process

Weathering ores on the surface around Dianchi Lake in Yunnan Province: Coarse grained ores have high enrichment of useful minerals and low impurity content. Coarse grained ores can be directly used as concentrate products, while fine-grained ores need to be enriched through flotation operations to obtain concentrate products. The specific principle process is as follows:

For more professional suggestions? Contact us!

Warm Tips:If you want to know more information, like quotation, products, solutions, etc.,

Contact: Pingheng

Tuxing Sun Mineral Processing Expert

Wechat/whatapp:+86 18092529083

Email:[email protected]

- Random article

- Popular articles

- Popular comments

- Gold Mine Gravity Beneficiation Process

- Scheelite Flotation Method

- Gravity combined beneficiation process for black and white tungsten ore

- Gravity combined beneficiation process for wolframite ore

- Laterite Nickel Ore: Pyrometallurgical Treatment

- Laterite Nickel Ore Hydrometallurgical Process for Oxide Ore

- Efficient purification of manganese ore by magnetic separation process

Leave a message with your needs or comments

Add comment: