The gravity separation and flotation process of tantalum niobium ore is a process that combines physical beneficiation (gravity separation) and chemical beneficiation (flotation) to improve the separation efficiency and grade of tantalum niobium minerals.

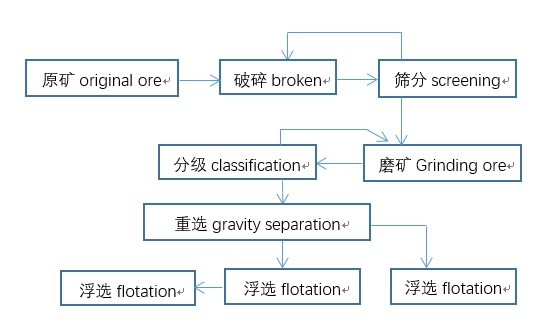

Process flow

1.Raw ore crushing:Crushing the raw ore into smaller particles for the subsequent beneficiation process.

2.Re selection:Use the density difference of minerals for separation. Re selection can be gravity beneficiation or strong magnetic beneficiation. During the re selection process, some tailings are removed, while the crude concentrate product enters the flotation operation.d

3.Flotation:Put the crude concentrate product obtained from re selection into the flotation machine. In the flotation machine, the flotation agent is added, and the minerals in the pulp interact with the flotation agent to form foam products. The minerals in foam products have high floatability and can be separated by foam.

4.Collection of foam products:collect the flotation foam products for further processing to obtain high-grade tantalum and niobium minerals.

5.Concentrate processing:the collected foam products are further processed, such as concentration and drying, to finally obtain high-grade niobium and tantalum mineral products.

Technological advantages

1.Efficient Separation:The combination of gravity separation and flotation processes can more effectively separate different types of minerals from the original ore, improving the enrichment degree of niobium and tantalum minerals.

2.Flexibility:Based on the characteristics of the ore and the specifications of the required products, the process parameters can be flexibly adjusted to achieve the best production effect.

3.Economy:Although the initial investment may be high, the long-term operating cost of the flotation process is low, and the economic benefits are significant.

4.Environmentally friendly:The flotation agents used in the flotation process are relatively environmentally friendly and have a relatively small impact on the environment.

5.Wide applicability:The flotation process is suitable for various types of ores and can process ores with different particle sizes and compositions.

The gravity separation and flotation process of tantalum niobium ore is an efficient and environmentally friendly beneficiation method that can improve beneficiation efficiency and product quality, while also having good economic and environmental benefits.

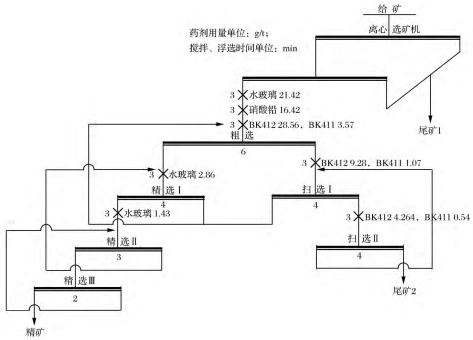

Typical beneficiation plant

Bernie Lake Tantalum Dressing Plant: The deposit is a granite pegmatite deposit, with main metal minerals including cassiterite, tin manganese tantalum ore, heavy tantalum iron ore, tantalum zirconium ore, tantalum tin ore, etc.

For more professional suggestions? Contact us!

Warm Tips:If you want to know more information, like quotation, products, solutions, etc.,

Contact: Pingheng

Tuxing Sun Mineral Processing Expert

Wechat/whatapp:+86 18092529083

Email:[email protected]

- Random article

- Popular articles

- Popular comments

- Tin ore flotation+gravity separation+magnetic separation process

- Understanding the Gold Mine Flotation Process

- Arsenic Gold Ore Oxidation Roasting Pretreatment Process

- Gravity combined beneficiation process for wolframite ore

- Laterite Nickel Ore Hydrometallurgical Process for Oxide Ore

- Zirconium Ore Separation: Gravity and Magnetic Methods

- Zirconium Ore Processing: Gravity, Magnetic, and Flotation Methods

Leave a message with your needs or comments

Add comment: