At present, there are only about 10 types of zirconium minerals with industrial value, mainly including zircon, hafnium containing zircon, and anisotropic minerals. The commonly used beneficiation methods include gravity separation, magnetic separation, electric separation, and flotation.

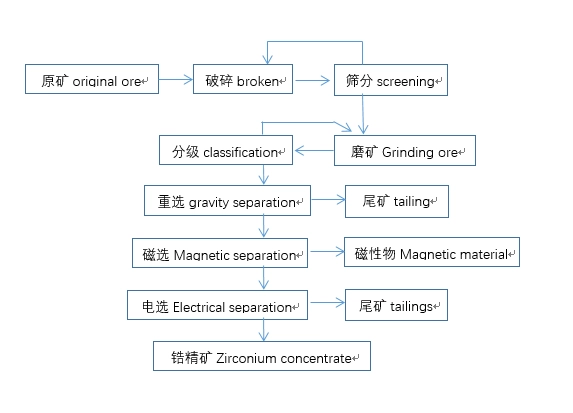

Gravity separation+magnetic separation+electric separation process

This process is currently the most widely used conventional zirconium selection process both domestically and internationally.

Process characteristics

High grade and diverse product types.

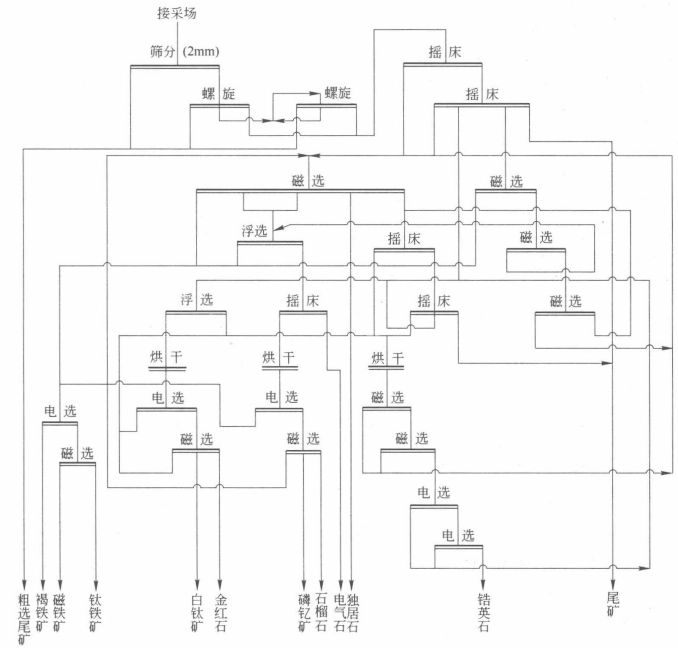

Typical beneficiation plant

Nanshanhei rare earth ore is a coastal sand deposit mainly composed of zircon and monazite, with low heavy mineral content and high light mineral content mainly composed of quartz. The specific process is as follows:

For more professional suggestions? Contact us!

Warm Tips:If you want to know more information, like quotation, products, solutions, etc.,

Contact: Pingheng

Tuxing Sun Mineral Processing Expert

Wechat/whatapp:+86 18092529083

Email:[email protected]

- Random article

- Popular articles

- Popular comments

- Lead-zinc Ore Asynchronous Flotation Process

- Branch serial flow flotation process for lead-zinc ore

- Processing Lithium Ore: Artificial Selection, Gravity Separation, Flotation

- chrome ore processing:Advanced Magnetic Separation Processing Technology

- Chromium Ore Gravity Separation and Flotation Process

- Understanding the Manganese Ore Flotation Process

- Manganese Ore Reduction Roasting and Magnetic Separation Process

Leave a message with your needs or comments

Add comment: