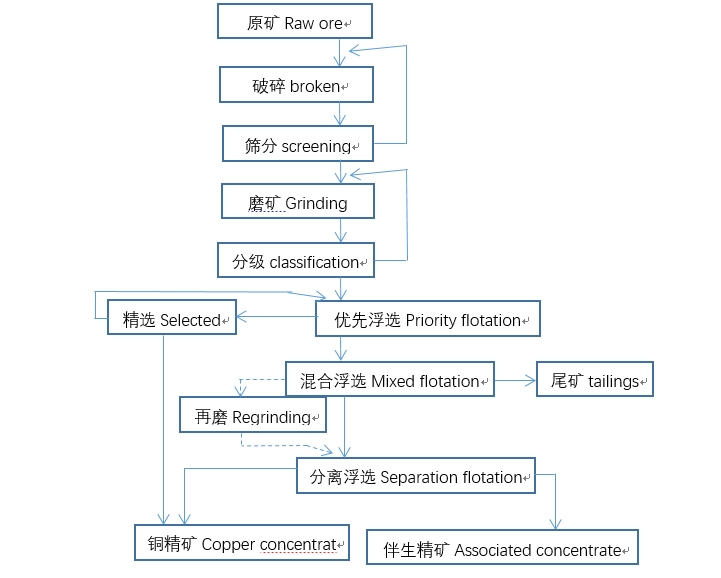

Partial priority (priority mixed) flotation method for copper ore is a flotation process that combines priority flotation and mixed flotation, suitable for treating copper ore containing multiple useful minerals. This method first enriches one of the useful minerals that is easy to float into a product based on the characteristics of the ore, then enriches other minerals with similar floatability into the mixed concentrate, and finally separates different minerals from the mixed coarse concentrate product to obtain different concentrate products.

Copper ore (partial priority+mixed) flotation process flow

1.Ore crushing:Crush the copper ore to an appropriate particle size for subsequent flotation operations.

2.Priority flotation: Based on the characteristics of the ore, select appropriate flotation reagents and conditions to enrich one of the easily floating useful minerals into a product.

3.Mixed flotation: The slurry after priority flotation is mixed for flotation, and other minerals with similar floatability are enriched in the mixed concentrate.

4.Concentrate separation: Separation of mixed concentrates enriched with various useful minerals to obtain different types of concentrate products.

In the partial priority (priority mixed) flotation method, the selection of flotation reagents and the control of flotation conditions are crucial. Different copper ores and useful minerals require the selection of different flotation reagents and conditions to achieve effective enrichment and separation.

Characteristics of flotation process for copper ore (partial priority+mixed)

1.A high-grade concentrate with a useful mineral can be obtained first, which is beneficial for subsequent smelting and processing.

2.Taking into account the comprehensive recovery rate of useful minerals, the economic benefits of the mine have been improved.

3.A large amount of tailings can be thrown away in advance at coarser grinding fineness, reducing grinding power consumption and production costs.

Partial priority (priority mixed) flotation method for copper ore is an effective flotation process for treating copper ore containing multiple useful minerals. It can improve the comprehensive recovery rate of useful minerals while obtaining high-grade concentrate, reduce production costs, and improve economic benefits.

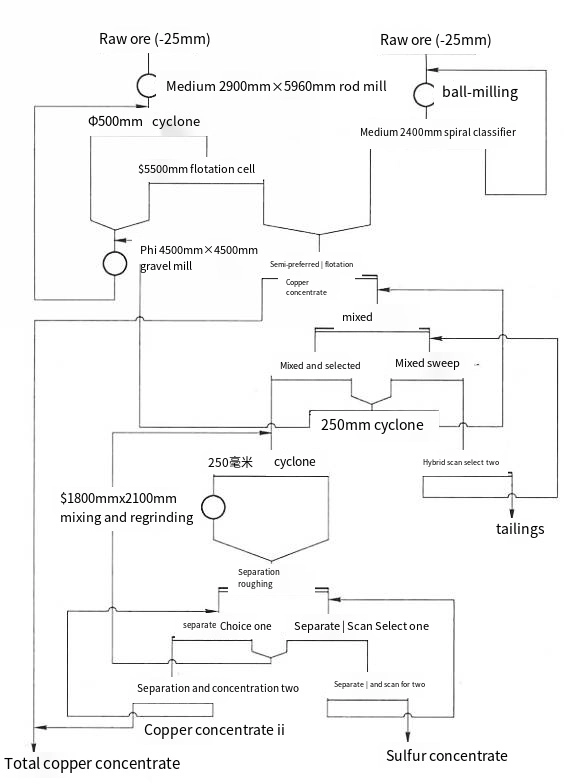

Typical beneficiation plant

Anhui Tongling Fenghuangshan Copper Mine Dressing Plant: The main useful minerals in the ore are chalcopyrite, bornite, pyrite, and colloidal pyrite; The semi priority copper sulfur mixed separation flotation process is adopted. Firstly, a portion of high-grade copper concentrate is obtained, followed by mixed flotation of difficult to select copper ore and associated minerals. The mixed concentrate is further ground and separated to obtain copper concentrate products and sulfur concentrate products, respectively. The specific process is as follows:

- Random article

- Popular articles

- Popular comments

- Hg-ore gravity separation process

- Hg-ore Gravity selection+flotation process

- Lithium ore magnetic separation process

- Lithium ore heavy medium beneficiation process

- Processing Lithium Ore: Artificial Selection, Gravity Separation, Flotation

- Zirconium Ore Processing: Gravity Separation and Flotation

- Complete Manganese Ore Gravity Separation Process

Leave a message with your needs or comments

Add comment: