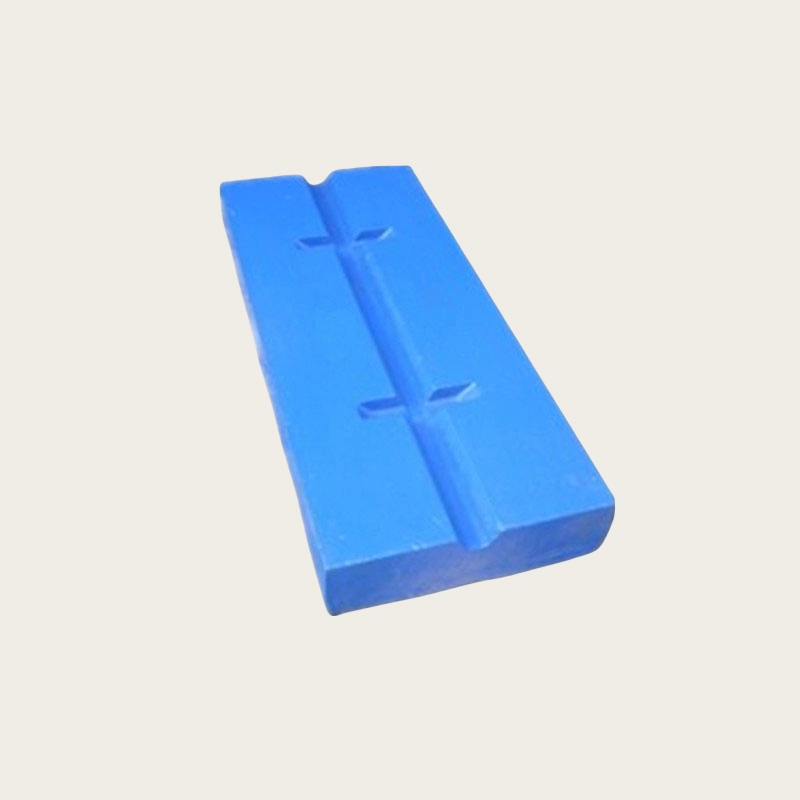

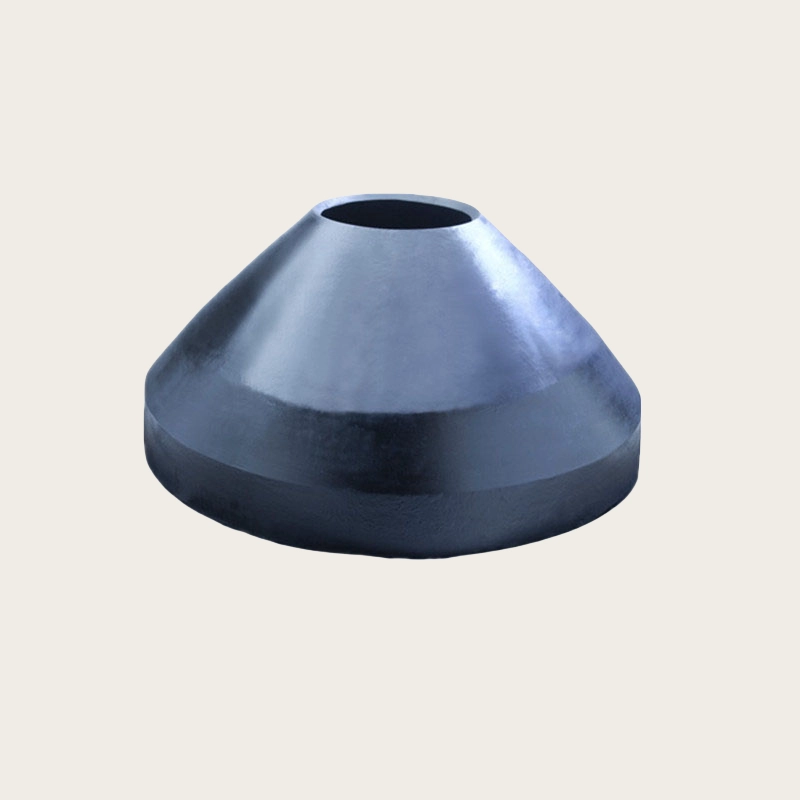

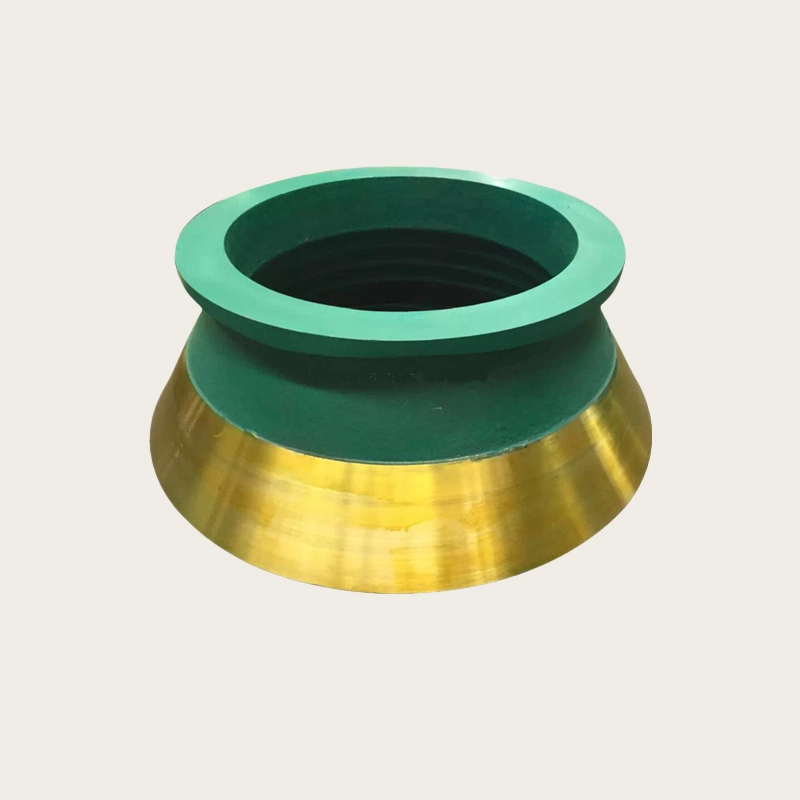

1.Introduction of Jaw Plate

Jaw plates of MES are manufactured with high manganese steel anti-wear materials, light weight, high intensity and rigidity.

Material:

| C | Si | Mn | P | S | Cr | |

| Mn13 | 0.9-1.05 | 0.3-0.9 | 11.0-14.0 | ≤0.060 | ≤0.040 | - |

| Mn12Cr2 | 1.05-1.35 | 0.3-0.9 | 11.0-14.0 | ≤0.060 | ≤0.040 | 1.5-2.50 |

| M18 | 1.05-1.35 | 0.3-0.9 | 16.0-19.0 | ≤0.060 | ≤0.040 | - |

| Mn18Cr2 | 1.05-1.35 | 0.3-0.9 | 16.0-19.0 | ≤0.060 | ≤0.040 | 1.5-2.50 |

2.Features and Advantages of Jaw Plate

2.1.Materials: high manganese and customised material.

2.2.Use: wear parts for crushers in the quarry, mining, cement aggregate, recycling, shredding and demolition fields. etc.

2.3.Certifications: ISO9001 &TS and CE certification.

2.4.Production quality testing: hardness testing, metallographic structure, machinery performance testing,ultrasonic inspection, high frequency infrared carbon and surface analysis etc.

2.5.Competitive products: good quality with reasonable price.

2.6.Strong wear resistance and long life span, can be used in harsh environment and serious abrasion.

2.7.Professional: our factory has over 10 years working experience in casting and forging process and manufacture.

2.8.We can provide customized design according to our clients’ demands and also refine our products by our clients’ feedback.

For more professional suggestions? Contact us!

Warm Tips:If you want to know more information, like quotation, products, solutions, etc.,

Contact: Pingheng

Tuxing Sun Mineral Processing Expert

Wechat/whatapp:+86 18092529083

Email:[email protected]

- Random article

- Popular articles

- Popular comments

- Gold selection process using resin slurry method

- Arsenic Gold Ore Bacterial Oxidation Pretreatment Process

- Scheelite Flotation Method

- Gravity combined beneficiation process for black and white tungsten ore

- Lithium Ore Processing: Gravity Separation and Flotation

- Understanding the Manganese Ore Flotation Process

- Tantalum-Niobium Ore Processing: Gravity, Magnetic, and Electric Separation

Leave a message with your needs or comments

Add comment: