At present, uranium is mainly extracted from uranium ores, and uranium containing phosphate ores, uranium containing copper mines, and uranium containing gold mines are also used as objects for uranium extraction; Most uranium ore in mines is directly subjected to chemical leaching after crushing and grinding. The beneficiation process of uranium ore is not a necessary part of uranium extraction. Only when the beneficiation operation can reduce production costs, will the beneficiation process be added to the uranium ore development process. Ordinary gravity separation, magnetic separation, and flotation methods are less commonly used in uranium ore beneficiation, while radioactive beneficiation is more commonly used.

Radioactive beneficiation

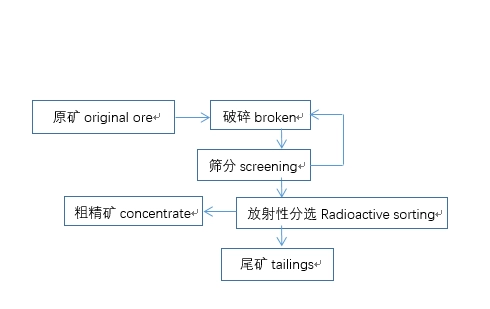

Radioactive beneficiation is a coarse-grained ore beneficiation method, in which the raw ore is crushed and graded, and directly enters the radioactive beneficiation equipment for sorting. Some large tailings can be discarded in advance.

Process features

low cost and simple equipment.

Typical beneficiation plant

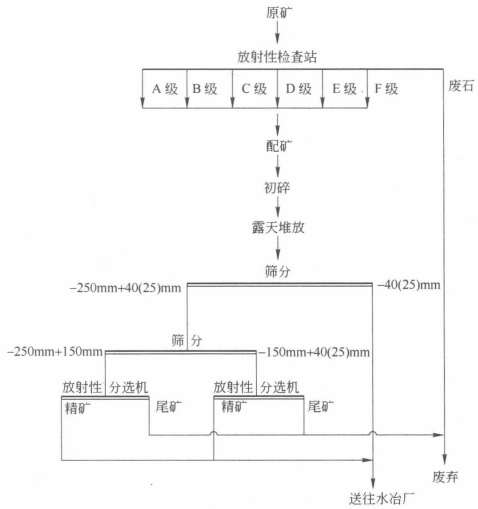

The Mary Katherine Radioactive Sorting Plant in Australia is a metamorphic uranium deposit located in a fractured zone of garnet rock composed of garnet, hornblende, diopside, orthoclase, and feldspar. The ore also contains small amounts of apatite, calcite, pyrrhotite, etc; Crystalline uranium ore is closely related to epidote and apatite. The sorting process is as follows:

For more professional suggestions? Contact us!

Warm Tips:If you want to know more information, like quotation, products, solutions, etc.,

Contact: Pingheng

Tuxing Sun Mineral Processing Expert

Wechat/whatapp:+86 18092529083

Email:[email protected]

- Random article

- Popular articles

- Popular comments

- Radioactive beneficiation and flotation process for uranium ore

- chrome ore processing:Advanced Magnetic Separation Processing Technology

- Manganese Ore Reduction Roasting and Magnetic Separation Process

- Effective Flotation Processes for Copper-Molybdenum Ores

- Essential Guide to Tantalum-Niobium Ore Flotation Process

- Efficient Tantalum-Niobium Ore Separation: Gravity vs. Flotation

- Understanding the Barite Flotation Process

Leave a message with your needs or comments

Add comment: