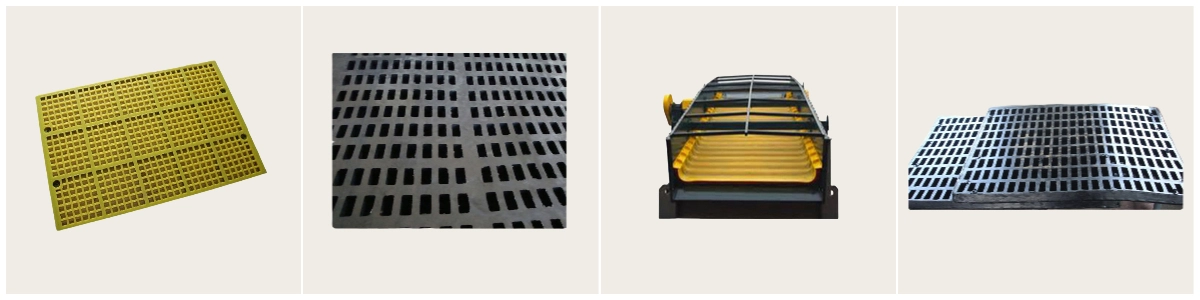

Rubber screen panel is an essential part for screening machine which is often used to sieve mineral particles or other objects. It is mainly used for raw coal ore grading,mineral separation etc. The service life of our rubber screen panel is 4-8 times than metallic screen panel.

1.Product Introduction

The rubber screen panel is an essential component of a screening machine, commonly used to sift mineral particles or other objects. It is primarily utilized for grading raw coal ore and mineral separation. In addition to its exceptional wear-life, rubber screen panels significantly reduce noise levels. Compared to perforated steel plates, noise reductions of up to 500% are typical.

Our rubber screen panels are well-suited for bottom deck applications where blinding is a concern. By leveraging the properties of the rubber compound, a high degree of flexibility across the working surface of the panels can be achieved, making it a perfect solution for screening sticky ores. Traditionally, polyurethane has had a longer life cycle than rubber in sliding abrasion applications. However, in a trial conducted in a bottom deck product screen application at an iron ore plant, our rubber screen panel compound lasted as long as the polyurethane panels.

2.Advantages

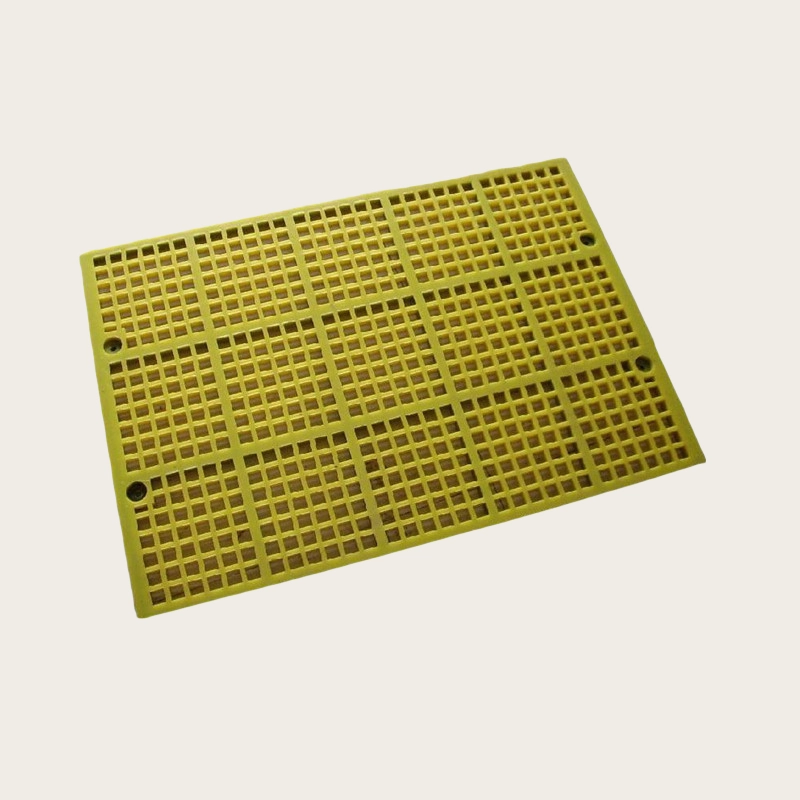

The service life of our rubber screen panel is 4-8 times than metallic screen panel.

Low noise,less dust. According to the field measurement,the wear-resistant rubber screen panel can reduce 5-20 decibel volume after compare with the metal screen panel, and can reduce the dust flying obviously,let the workshop gets a quiet clean work environment.

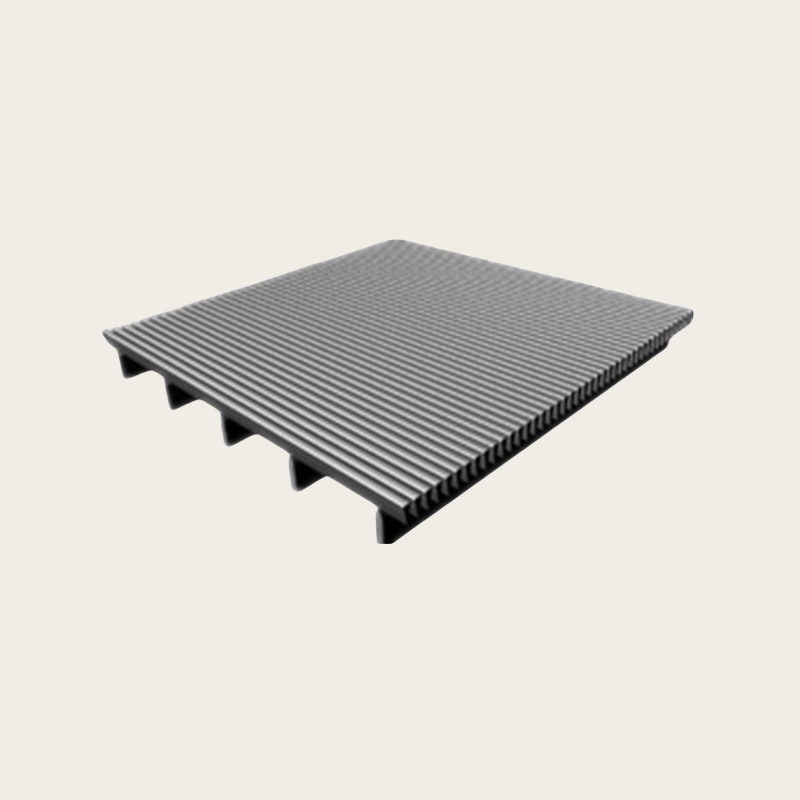

Proportion is small,easy to install,easy to loading and unloading or transportation. One square meter of 15 mm thick rubber screen panel is less than 15 kg, it not only can lose the weight of equipment,but also reduce the power consumption of the screening machine.

We embedded the metallic framework in our product,it has the uniform perforation,so our product has a better abrasion performance.

Because of the structure of wear-resisting rubber screen panel, it can make the hole of rubber screen panel have the relaxation performance,and screen hole like the taper,so it is not easy to plug hole,and has good self-purification ability.

It has the high screening accuracy.The perforation of our product has a expansive function,so it hard to be blocked.

We can produce rubber screen panel with special specification according to your requirement.

3.Application

Specifically designed for all mining and quarry industries.

Sieving ore like gold, iron,aluminum,coal,copper,stone etc,liquor separation like separate water from cement.

.Abrasive material and ceramic industry: building sand, mica, alumina, abrasive, refractory material, slurry, etc.

Chemical industry: resin pigment, medicine, grease, paint, palette, etc.

We can provide customized design according to our clients’ demands and also refine our products by our clients’ feedback.

For more professional suggestions? Contact us!

Warm Tips:If you want to know more information, like quotation, products, solutions, etc.,

Contact: Pingheng

Tuxing Sun Mineral Processing Expert

Wechat/whatapp:+86 18092529083

Email:[email protected]

- Random article

- Popular articles

- Popular comments

- Priority flotation process for copper ore

- Arsenic Gold Ore Oxidation Roasting Pretreatment Process

- Arsenic Gold Ore Bacterial Oxidation Pretreatment Process

- Nickel ore magnetic separation+flotation combined process(Sulfide ore)

- Lithium ore positive flotation process

- Effective Gravity Beneficiation for Chromium Ore

- Efficient purification of manganese ore by magnetic separation process

Leave a message with your needs or comments

Add comment: