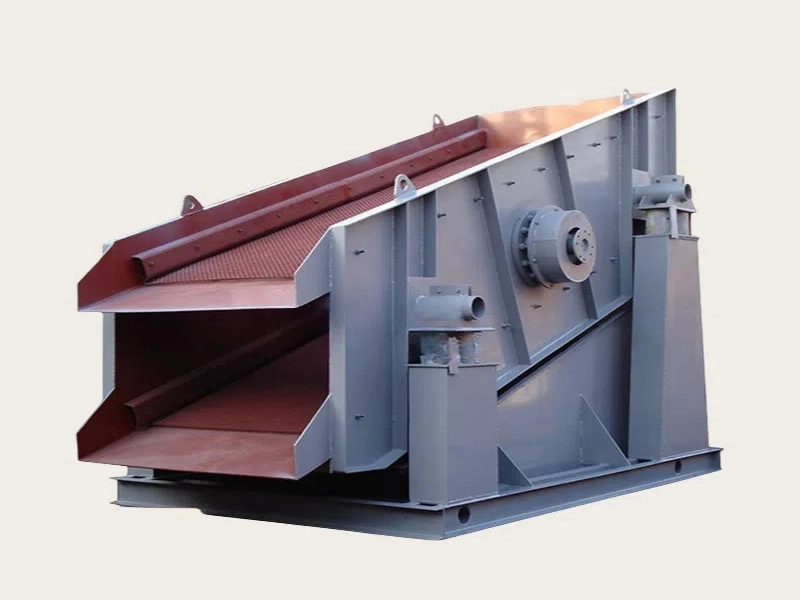

800Efficient circular vibrating screen is a kind of multi-layer, high-efficiency new vibrating screen developed by us.

Description

Name: circular vibrating screen, vibrating screen

Length of screen surface: 6000mm

Material trajectory: approximate circular motion

Processing capacity: 20-500t / h

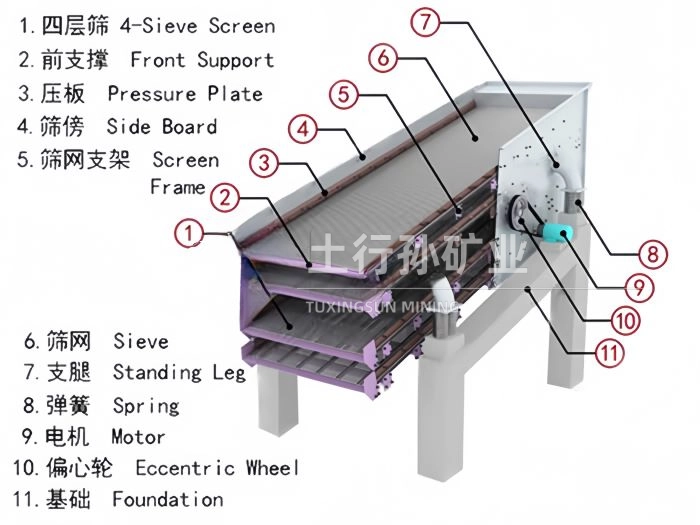

Vibrating screens are primarily composed of spring base, rotating mandrel, pulley, screen, aggregate, eccentric block, bearing, excitation wall, screen box, and motor.

Circular vibrating screens have circular vibrations, multiple layers, and high efficiency, and are a relatively new type of vibrating screen. Among its characteristics are a sturdy and durable structure, a powerful excitation force, high screening efficiency, low vibration and noise, and easy maintenance. In mining, building materials, transportation, energy, chemical, and other industries, it is widely used for product classification.

Advantage

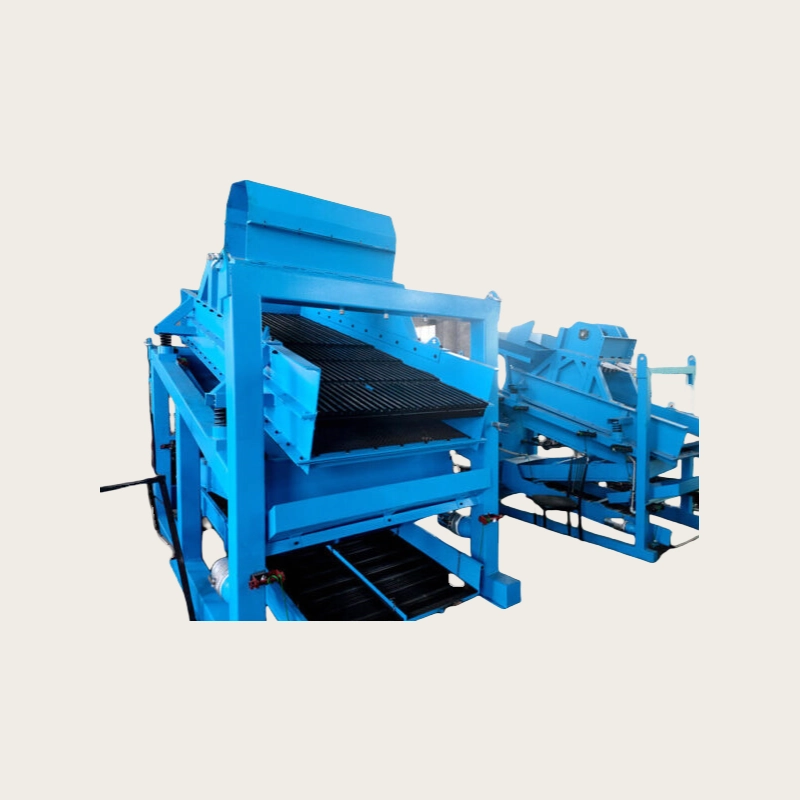

This product contains wear-resistant blocks and other important parts. Its simple structure makes maintenance simple. Unlike welding, both the screen and screen box are integrally sheathed with bolts, preventing splitting caused by vibration and making replacement convenient. The vibrating screen is a common screening machine used for coal, mineral processing, and other industries for material classification, washing, dehydration, and de-intermediation. The linear vibrating screen is also known as the dual-axis inertial vibrating screen, which is an inertial vibrating screen. It is widely used due to its high production efficiency, good classification effect, convenient maintenance, small size, lightweight, high efficiency, and many layers. Vibrating screens’ dynamic performance directly affects their screening efficiency and service life during operation.

Working Principle

A vibrating screen uses a vibrating motor as the source of vibration, so that material is thrown up on the screen and moves forward in a straight line. Undersized material is discharged from one outlet and oversize material from the other. The linear vibrating screen (linear screen) has the advantages of being stable and reliable, low consumption, low noise, long lasting, stable vibration shape, and high screening efficiency. A new type of screening equipment with high output and widely used in mining, coal, smelting, building materials, refractory materials, light industry, chemical industry, and other fields.

Vibrating screen performance characteristics

1.It is possible to adjust the angle of inclination of the vibrating screen with the spring base;

2.In order to prevent damage due to torsion when the motor is started, the motor has a tire coupling;

3.An eccentric vibration exciter is used, and the excitation force is relatively strong;

4.By reducing the vibration of the vibrating screen body, the components can function normally under reduced pressure;

5.By using high-strength bolts for integral connections, the screen body is more durable under high-amplitude vibration and is less prone to breaking.

6.To reduce the wear of the excitation wall, a wear-resistant block is installed, which is sturdy and durable;

7.The screen has three layers to make the material screen finer;

8.There are bolts that hold the screen together as a whole, which makes it easy to replace;

| Model | Layer | Screen area(m2) | Screen size(mm) | Max screen size(mm) | Capacity(t/h) | Vibrating frequency(r/min) | Power(kw) | Dimension(mm) |

| 3YS1236 | 3 | 12.96 | 3-50 | 150 | 20-80 | 800-970 | 7.5 | 1200*3600 |

| 4YS1236 | 4 | 14.4 | 3-50 | 150 | 20-85 | 800-970 | 7.5 | 1200*3600 |

| 2YS1548 | 2 | 14.4 | 5-50 | 200 | 40-196 | 960 | 15 | 1500*4800 |

| 3YS1548 | 3 | 21.6 | 5-50 | 200 | 40-216 | 960 | 15 | 1500*4800 |

| 4YS1548 | 4 | 28.8 | 5-50 | 200 | 40-220 | 960 | 15 | 1500*4800 |

| 2YS1854 | 2 | 19.44 | 5-100 | 300 | 63-486 | 960 | 22 | 1800*5400 |

| 3KY1854 | 3 | 29.16 | 5-100 | 300 | 63-500 | 960 | 22 | 1800*5400 |

Application field

Vibrating screens can be used to screen stones, sand, and various ores, such as cinder, slag, lime, calcium carbonate, etc. It is mainly used along with jaw crushers, impact crushers, sand making machines, and other crushing equipment to complete the work. The product has been widely used in mining, coal, energy, building materials, road and bridge construction, and anti-corrosion in building construction, and has been praised by many.

For more professional suggestions? Contact us!

Warm Tips:If you want to know more information, like quotation, products, solutions, etc.,

Contact: Pingheng

Tuxing Sun Mineral Processing Expert

Wechat/whatapp:+86 18092529083

Email:[email protected]

- Random article

- Popular articles

- Popular comments

- Sand gold beneficiation process

- Gravity combined beneficiation process for black and white tungsten ore

- Laterite Nickel Ore Hydrometallurgical Process for Oxide Ore

- Lithium ore heavy medium beneficiation process

- Zirconium Ore Processing: Gravity, Magnetic, and Electric Separation

- Manganese ore washing to achieve the best results

- Complete Manganese Ore Gravity Separation Process

Leave a message with your needs or comments

Add comment: